|

Versatile and efficient, Seal vacuum presses are automatically self adjusting so you can process mounting boards of varying thickness simultaneously. And because the vacuum removes moisture, pre-drying your work is not necessary. Seal vacuum presses come ready to use with vacuum pumps and connecting assemblies for rapid installation. . |

|

VacuSeal Combination Presses |

|

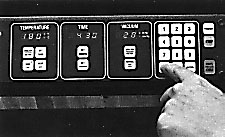

For years an industry standard, today's combination VacuSeals use digital microprocessor technology and touch pad controls to make operation easier, improve production consistency and maximize operator training time. The combination VacuSeal's Programmable Systems Controller allows you to to select from six factory installed programs for temperature and time or easily preset your own combinations. Just a few simple keystrokes selects and activates the desired program. Plus, easy to read digital displays and an audible end of cycle signal keep you informed of all operations. Featured in every VacuSeal press is a unique Programmable System Controller with six factory installed programs for temperature and dwell time, plus the option to easily preset your own combinations. Digital displays and an end-of-cycle signal let you go about your business and still keep on top of the press operations. VacuSeal presses are constructed with a sturdy Dura-Box alloy frame that provides a tight vacuum seal and extra durability. A space-saving work surface and maintenance-free vacuum pump make the press even more convenient and efficient. The Professional's Choice For

Professional Results

Giving You the Ultimate

Production Advantage

. |

|

Seal Dry Mount Vacuum Presses

. xxTechnical

Specifications

Work Capacity Dimensions Net Weight Shipping Weight Pressure Power Requirements Power Consumption Floor Stand * Specifications subject to change

with out notice .

VacuSeal

5298HVacuSeal

4468HVacuSeal

3648H

48" x 96" x 1"

44" x 68" x 1"

36" x 48" x 1"

107.25" x 65" x

37.25"

76.25" x 56.5" x

6.5"

52.25" x 45.5" x

6.5"

375 lbs.

Press - 205 lbs.

Pump - 10.5 lbs.Press - 115 lbs.

Pump - 10.5 lbs.

800 lbs.

495 lbs.

325 lbs.

13 psi

13 psi

13 psi

230 VAC

23 Amps

Single Phase

4 wire

NEMA L14-20 plug230 VAC

15 amps

Single Phase

4 wire

NEMA LI4-20 plug230 VAC

11 amps

Single Phase

4 wire

NEMA LI4-20 plug

Approx. 3390 watts

@ 230 VAC (15 amps)Approx. 1700 watts

@ 230 VAC (8 amps)

Built-in

UL ListedOptional

UL ListedOptional

UL Listed

| Seal 500 TX Dry Mount Press-

(under construction) |

||

Seal vacuum presses are designed for fast, easy mounting, laminating and texturing of a wide range of prints, photos and artwork with professional results.

Seal vacuum presses are designed for fast, easy mounting, laminating and texturing of a wide range of prints, photos and artwork with professional results.